WHY CHOOSE QUANTUM FOR YOUR FORMING SYSTEM?

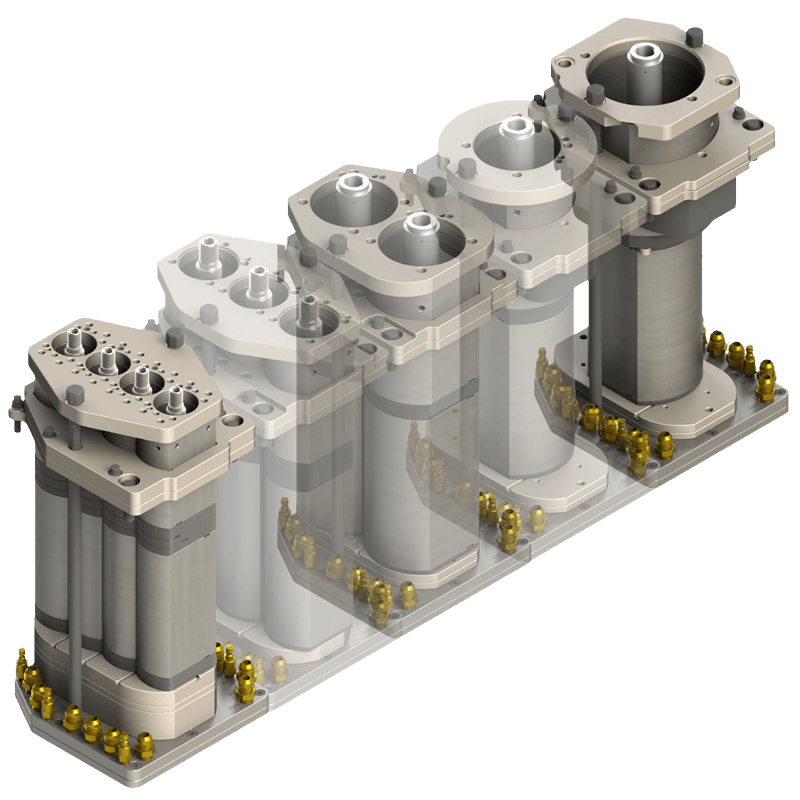

TWT® Design

- The patented Tube Within a Tube concept remains the best delivery system for Cooling, Counter Blow, or Vacuum Service to the Forming Plunger Mechanism

- TWT® Design Safeguards against “tramp glass”

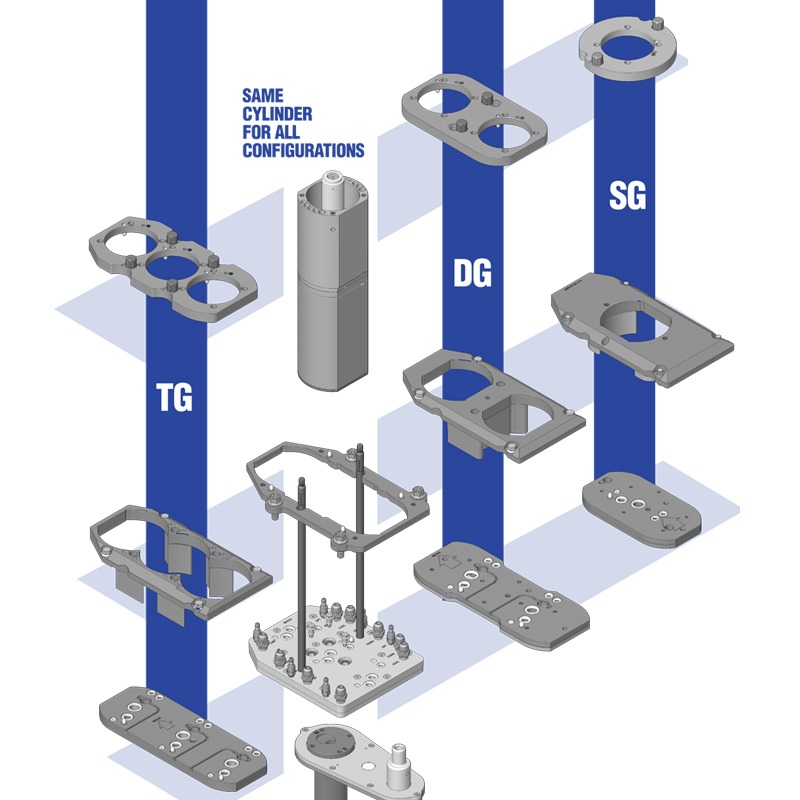

Universal Cylinder Concept

- Interchangeable components for any Center Distance and Gob Configuration in any factory requirement

- Alignment is a function of Design not-operator skill

Unique Forming Systems

- B&B, Press & Blow, NNPB, and Advanced Blow and Blow Forming Systems have been designed for Trouble-Free Operation

- Minimized mechanical problems allow greater attention to the rest of the Forming Process

- All Quantum Cartridges are Internally Lubricated for long life

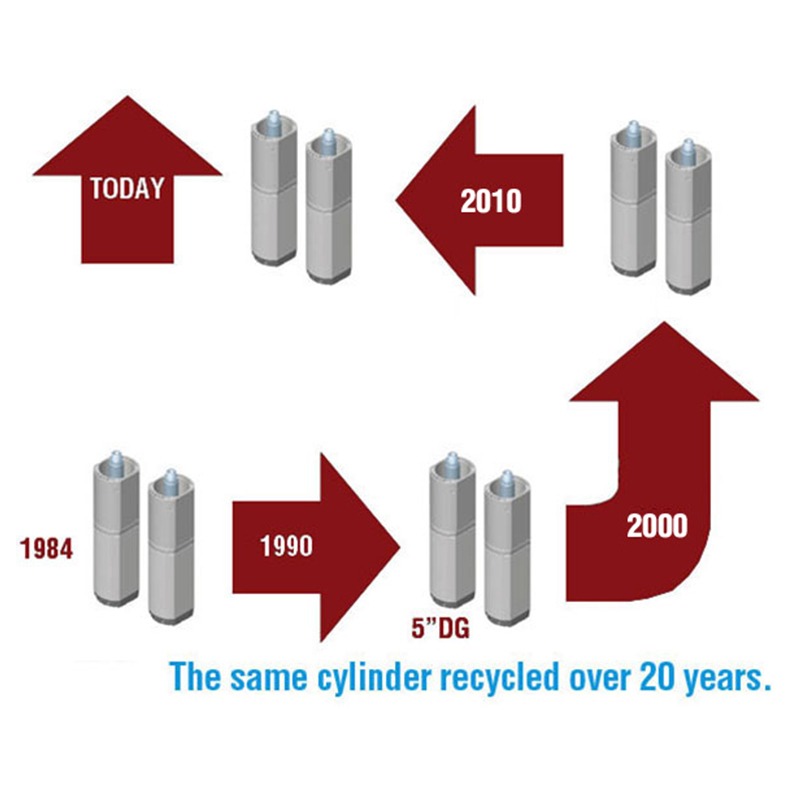

Maximum Return on Investment

- Quantum Components are made with Alloyed tool steels, proprietary heat treatment, and unique coating surface infusion techniques

- Once produced basic components have an indefinite life

- Quantum units supplied in 1980 are still running in the state of the art machines today

Maximum Production Flexibility

- The Quantum System can be reconfigured for different center distances and gob configurations

- As market demands require, The Quantum Forming System is ready to adapt at minimal investment

Contact Us

If you have any questions about our products or services please let us know

Request A Quote

To request a quote for our products or services please tell us how we can help!