|

|

Recycling one glass bottle can save enough energy to power a computer for 25 minutes!

|

At Quantum our values and goals align with those of our customers. We aim to help the industry produce lighter, stronger, and more eco-friendly glass packaging. By solving our customers blank side forming problems we help them to minimize production defects, wasted glass, and wasted energy. Using sustainable methods of production is key to the growth of our industry, and bringing awareness to the benefits of recycling glass is essential to the future of glass packaging.

Glass is 100% recyclable and can be reused an infinite number of times without losing any of the purity and quality of the original glass. When glass is not recycled, it is sent to landfill, where it will never fully decompose. However, if that same glass had been recycled, it can be back the on shelf at your local grocery store in as little as thirty days as a completely new container!

Today, some glass manufacturers are using up to 90% recycled glass, called cullet, in their production process. Quality cullet is in high demand by glass manufacturers all over the world. Using cullet in glass container production is very cost effective. For every 10% of the glass batch that is comprised of cullet the energy required for production is reduced by two to three percent. The energy savings is due to the fact that cullet melts at a much lower temperature than the raw materials used to make virgin glass containers. Reducing energy consumption, in turn, reduces greenhouse gas emissions, which creates a more environmentally friendly product. In addition, the use of cullet can also extend the life of a glass furnace itself because of the lower temperature required for melting. Given this information, along with the increasing governmental pressure for sustainability, it is in the glass industry’s best interest to use as much recovered material as possible in its products. This is an important initiative that must be taken to help glass remain competitive with alternative packaging.

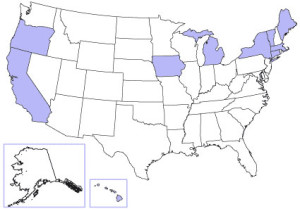

In order to benefit from the use of cullet in glass production, the manufacturers must rely on consumers to recycle. Even though many people understand the basic benefits of recycling glass, there is still more demand for high quality cullet than there is a supply. According to the EPA, as a whole The United States’ glass recycling rate is around 30%. When this number is compared to many European countries, which are recycling at rates of 90% and higher, it is clear that the U.S. is lagging far behind in our efforts to improve the sustainability of the industry. There are a number of reasons why the U.S. has such a poor recycling rate, but perhaps the biggest reason is a lack of incentive to recycle. Only ten out of the fifty U.S. states give an incentive to recycle. In these states there is a deposit paid by the consumer at the point of sale. When consumers return the glass container to a recycling center, they are then refunded their deposit. The effectiveness of this financial incentive is realized when you consider that the U.S. states that have an active “bottle bill,” recycle at much higher percentages than the states that do not.

U.S. states that have an active “bottle bill”

-Oregon -California

-Iowa -Michigan

-New York -Vermont

-Massachusetts -Connecticut

-Maine -Hawaii

Some other reasons Americans give for not recycling include: recycling is not readily available or offered in their area, it takes too much effort to recycle, it costs too much to recycle in their area, people are too busy to recycle and some believe that it doesn’t make a difference. These reasons lead to glass ending up in a landfill or as litter when it could have been melted and formed into another container. In the years to come it will be the responsibility of the glass container industry to spread the facts about recycling and encourage individuals, and governments, to make intelligent and responsible decisions.

|

|

9 out of 10 people would recycle if it were made easier

|

|